What makes this new Gregario Vera AR aero highway bike distinctive isn’t simply considerably unconventional shaping, however somewhat the patented manufacturing strategies used to create full {custom} geometry and match on this monocoque carbon bike. Gregario employs a extremely adjustable, modular mould system to create this aerodynamic highway body in a single piece from steady carbon fibers, absolutely retaining the flexibility to regulate dimensions and body angles to individually go well with every bike owner.

It’s a challenge the crew behind the bike has been engaged on for greater than 8 years, simply now prepared for shoppers. The primary business orders had been positioned simply final month, and the primary buyer bikes can be out of the mould this month, touchdown Gregario the prize for Greatest New Builder on the Bespoked handmade bike present in Dresden over the weekend.

Gregario Vera AR absolutely {custom} monocoque aero highway bike

Gregario calls the Vera AR the “final bespoke bike”. It’s an aero monocoque carbon highway bike with aerodynamics optimized in CFD for contemporary vast highway tires and disc brakes. However on the similar time, it retains all of the geometry and match customization you’d usually affiliate with a extra conventional-looking bike.

How and why did {custom} geometry monocoque development develop?

Based in northern Italy by an ex-3T design engineer and a analysis engineer from Politecnico di Torino, Italy’s first engineering college, Gregario got down to rethink bicycle manufacturing with their patented “variable geometry mould know-how”.

Customized geometry carbon bikes are usually made with tube-to-tube development, very like standard metallic bikes. And plenty of semi-custom and even some stock-size carbon bikes are made by individually molding numerous entrance triangles, after which bonding a rear finish onto them after having been partially cured. Both technique ends in additional joints that require extra materials to realize the specified energy, or might even introduce a possible failure level if there may be any drawback with bonding. That’s why bike makers so make use of it, tout their monocoque development strategies. However traditionally, that has meant one full monocoque mould is required for every monocoque body dimension.

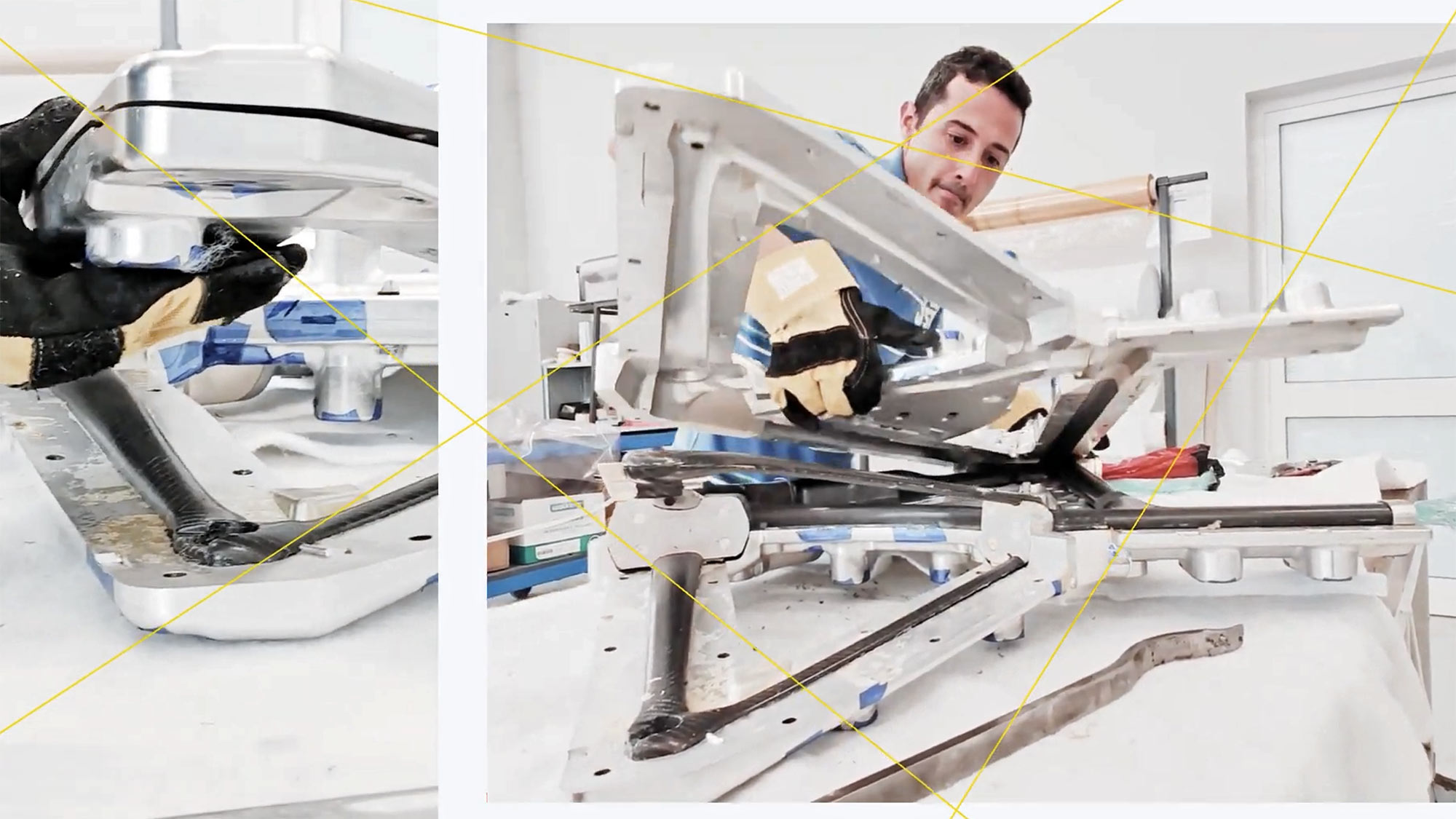

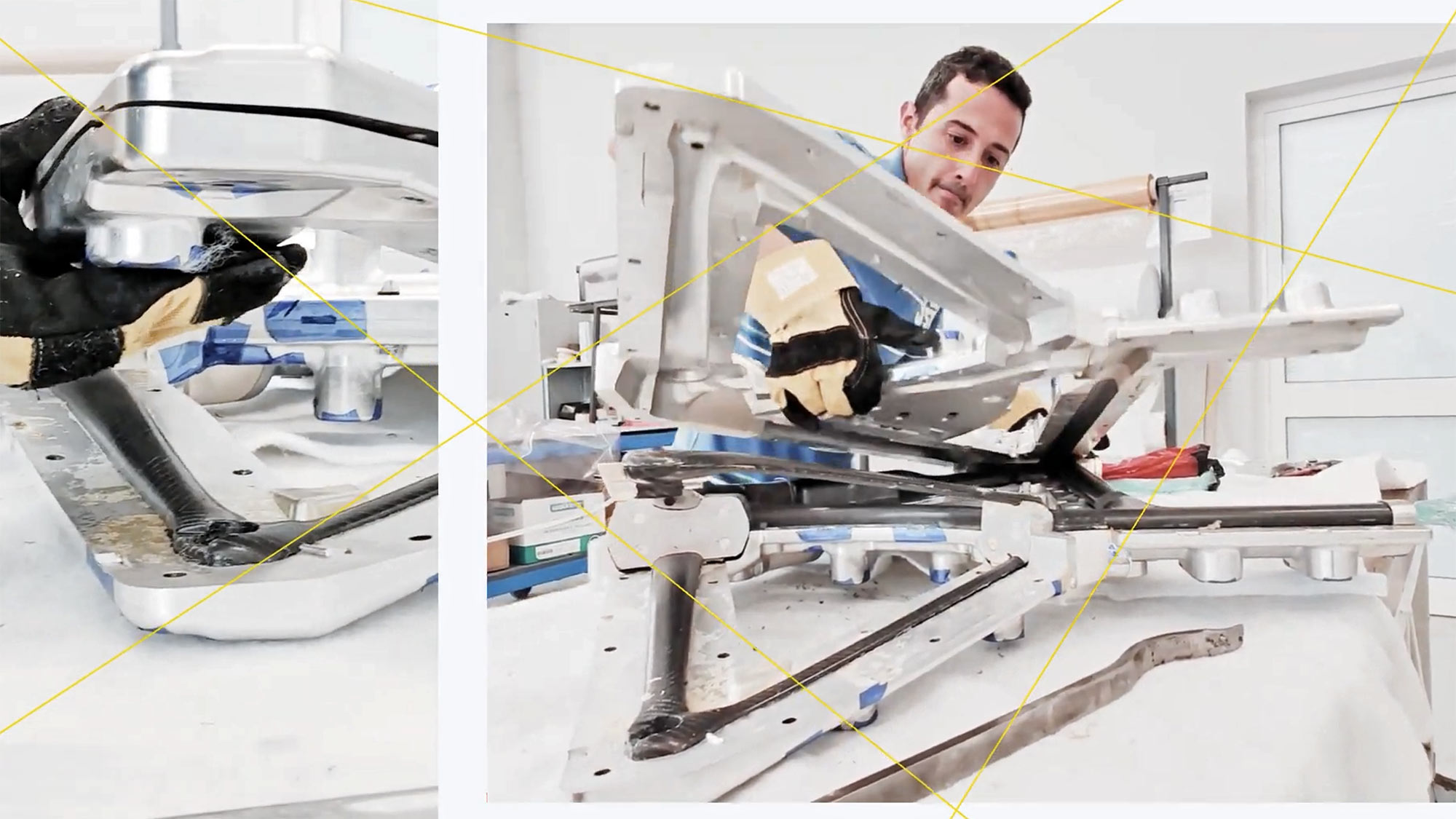

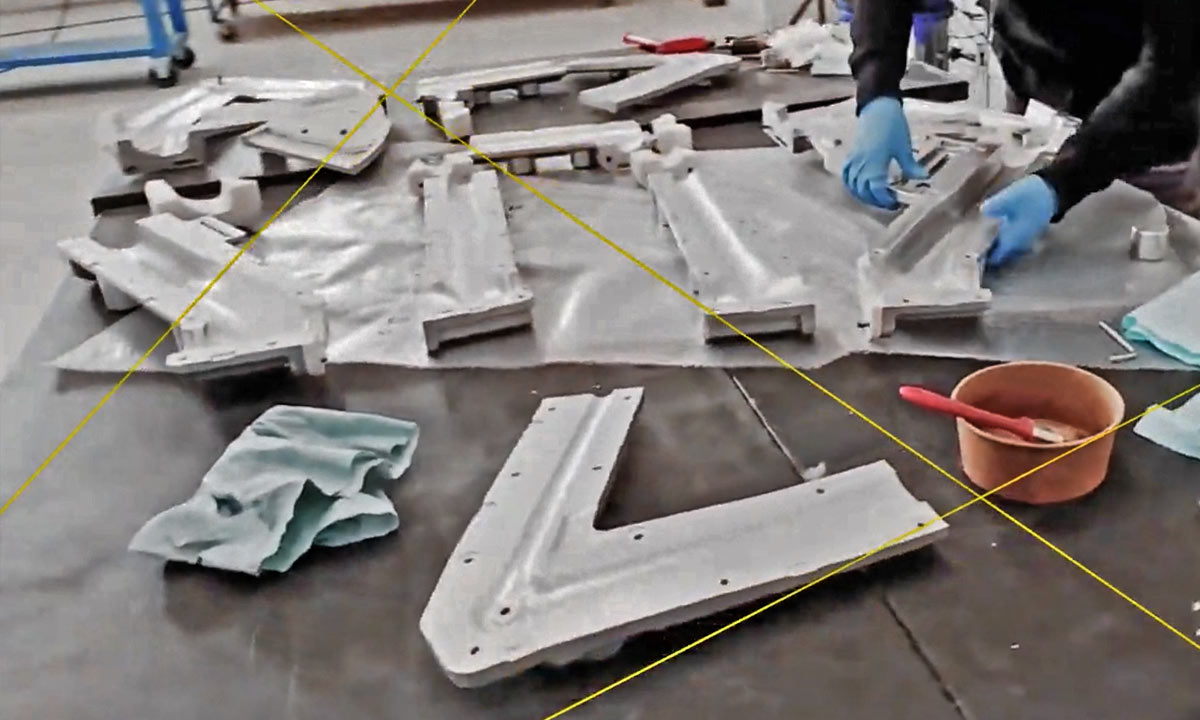

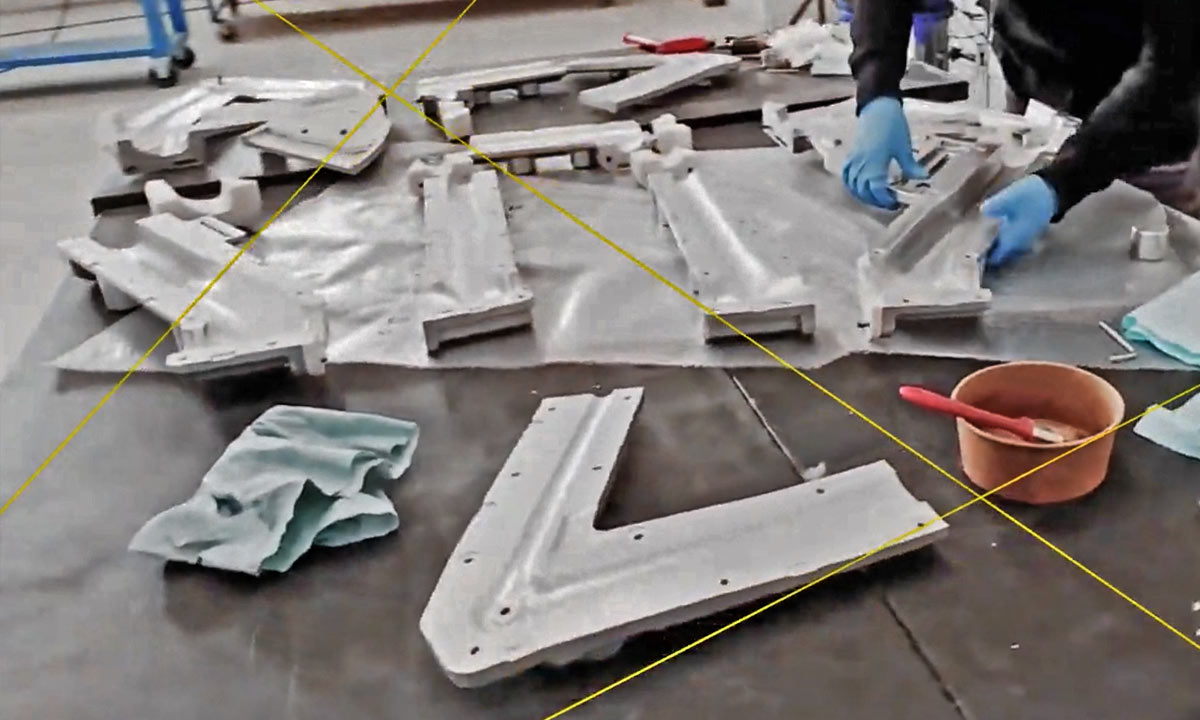

Gregario’s core know-how is mainly a novel multi-part, mixed-material modular body mould that enables Gregario to range the lengths and angles between one tube junction and the following. By combining modular mould components after which inserting additional segments into the mould, they’ll range particular person body tube lengths by the millimeter, thus tweaking body sizing and geometry to every rider. On the similar time, sustaining key tube junction shaping and total body design. And in the long run, an entire one-piece mould closes like a clamshell – identical to a traditional single-size monocoque mould – to kind and autoclave remedy your entire body as a single piece.

A more in-depth look

The adjustable molds that make Gregario’s {custom} bike nonetheless produce the sleek shapes and integration we’ve come to count on from fashionable aerodynamic bikes – versus extra standard spherical tube-to-tube development.

In actual fact, that shaping functionality is strictly why Gregario determined that their first manufacturing body could be an aero highway bike. The aero tube transitions and dramatic rear wheel cutout had been good to focus on how their body manufacturing might match essentially the most superior fashionable carbon bike shaping whereas retaining geometry customization.

One of many attention-grabbing issues concerning the adjustable Gregario development is that seams between particular person segments of the molds stay faintly seen within the uncooked carbon frames.

Within the picture above, you possibly can see two faint strains above the seatstays and two in entrance of the seat cluster on the highest tube. However on the similar time, you possibly can see that the 5HS weave of the T1100S 12K carbon fiber cloth is steady throughout these parting strains within the mould.

Customization ideology

Your complete Gregario {custom} course of is centered round designing the bike to suit completely beneath the person bike owner’s contact factors. That signifies that a motorcycle match is essential. However Gregario additionally developed an easy-to-use Digital Sizing on-line app to simplify and pace up that course of.

That additionally means it’s not solely concerning the bike. So that they created a {custom} cockpit answer that provides you your good bar width, angle, and stem size, however retains adjustability. Their two-piece bar answer may even independently alter stem and bar angles so you possibly can all the time have the perfect and most comfy match on the bars, even when your flexibility adjustments.

In the end, Gregario desires to construct you a motorcycle that you just’ll be blissful to trip for a few years to come back. So, to keep up ‘adaptability over time’, they designed the Vera AR with a stem that adjusts from -3° to +10° and the built-in seatpost design that maintains ±30mm of top adjustability.

Tech particulars

{custom} monocoque hi-mod carbon body weight from 840g

made-to-measure {custom} sizing

absolutely built-in inner cable routing by the 1.5″ higher headset

tapered 1.25-1.125″ fork from 360g

wi-fi, digital, and mechanical 1x & 2x drivetrain compatibility

detachable bolt-on entrance derailleur hanger

700x32mm max tire clearance

threaded T47 backside bracket

flat mount disc brakes and 12mm thru-axles

100% made in Italy

Gregario Vera AR – Pricing, choices & availability

The {custom} Gregario Vera AR aero highway bike is out there in a number of choices to fit your wants. And naturally, {custom} paint jobs are fully as much as the client, as properly.

Begin with a primary frameset from ~7320€ , together with: body, fork, and the proprietary seatpost. The entire body package provides within the custom-sized two-piece Vera handlebar & stem cockpit for a complete of 8662€. Full bike builds are additionally an choice, like this “Italian Flagship” construct with made-in-Italy Campagnolo Tremendous Document 13 groupset and Bora WTO wheels for 15,000€.

(Observe: All costs embrace 22% Italian VAT, which varies by nation, and exclude different importing and supply prices.)

Begin your {custom} aero highway bike challenge immediately with Gregario.

GregarioCycling.com